In the high-stakes world of aviation, reliability is paramount, especially when it comes to power. Imagine an aircraft soaring at 35,000 feet, its engines constantly varying speed to meet the demands of flight. Yet, crucial systems – from cockpit avionics to passenger lighting and fly-by-wire controls – demand an absolutely unwavering electrical supply. This incredible feat of engineering, ensuring stable power regardless of engine dynamics, hinges on the Principles of Integrated Drive Generator Operation. It's a testament to ingenious design, combining hydraulics and electrical generation into a single, indispensable unit.

Without the sophisticated dance performed by an Integrated Drive Generator (IDG), the smooth, constant 115/200 V, 400 Hz, 3-phase AC power that modern aircraft rely on simply wouldn't exist. This guide will pull back the curtain on how these essential components work, why they're so critical, and what makes them a marvel of aerospace technology.

At a Glance: What You'll Learn About IDGs

- The Core Problem: Aircraft engines run at variable speeds, but sensitive electrical systems need constant frequency AC power.

- The IDG's Solution: A self-contained unit combining a Constant Speed Drive (CSD) and an electrical generator.

- How it Works (Simply): The CSD takes variable engine speed and converts it into a constant speed for the generator, which then produces stable electricity.

- Key Output: A consistent 115/200 V, 400 Hz, 3-phase AC supply.

- Vital Systems Powered: Avionics, lighting, environmental controls, and critical fly-by-wire systems.

- Oil's Critical Role: It's not just for lubrication; oil also cools the unit and controls the CSD's speed.

- Maintenance Matters: Proper oil levels, quality, and monitoring are non-negotiable for safe operation.

Why Consistent Power is Non-Negotiable in the Sky

Modern aircraft are, in many ways, flying computers. Their intricate systems, from navigation displays to hydraulic pumps and even the basic cabin lighting, rely on a stable and predictable electrical current. Specifically, large transport-category aircraft standardize on a 115/200 V, 400 Hz, 3-phase Alternating Current (AC) supply.

The challenge? Aircraft engines, when operating, don't spin at a constant RPM. They speed up for takeoff, slow down for cruise, and idle on the ground. A direct drive from a variable-speed engine to a generator would result in a wildly fluctuating electrical frequency, making it impossible to power sensitive electronics reliably. This is precisely where the engineering brilliance of the Integrated Drive Generator shines, bridging the gap between an engine's dynamic output and an aircraft's rigid power requirements.

The IDG's Core Mission: Bridging Variable and Constant

At its heart, an IDG is a master of transformation. It takes the mechanical energy from the engine's accessory gearbox, which fluctuates with engine RPM, and transforms it into a precisely controlled, constant-speed input for an electrical generator. This ensures that the generator consistently produces the stable 400 Hz AC power the aircraft needs, regardless of what the engine is doing.

This process isn't just about convenience; it's about safety, efficiency, and the very capability of flight. Without this stable electrical backbone, many modern aircraft systems – especially those with digital components or frequency-sensitive motors – would simply fail to operate correctly, or at all. When you consider the vast array of systems relying on this power, from flight controls to the cabin's heating and cooling, the ingenuity behind how Integrated Drive Generators function becomes even more apparent.

Anatomy of an IDG: Two Marvels in One Unit

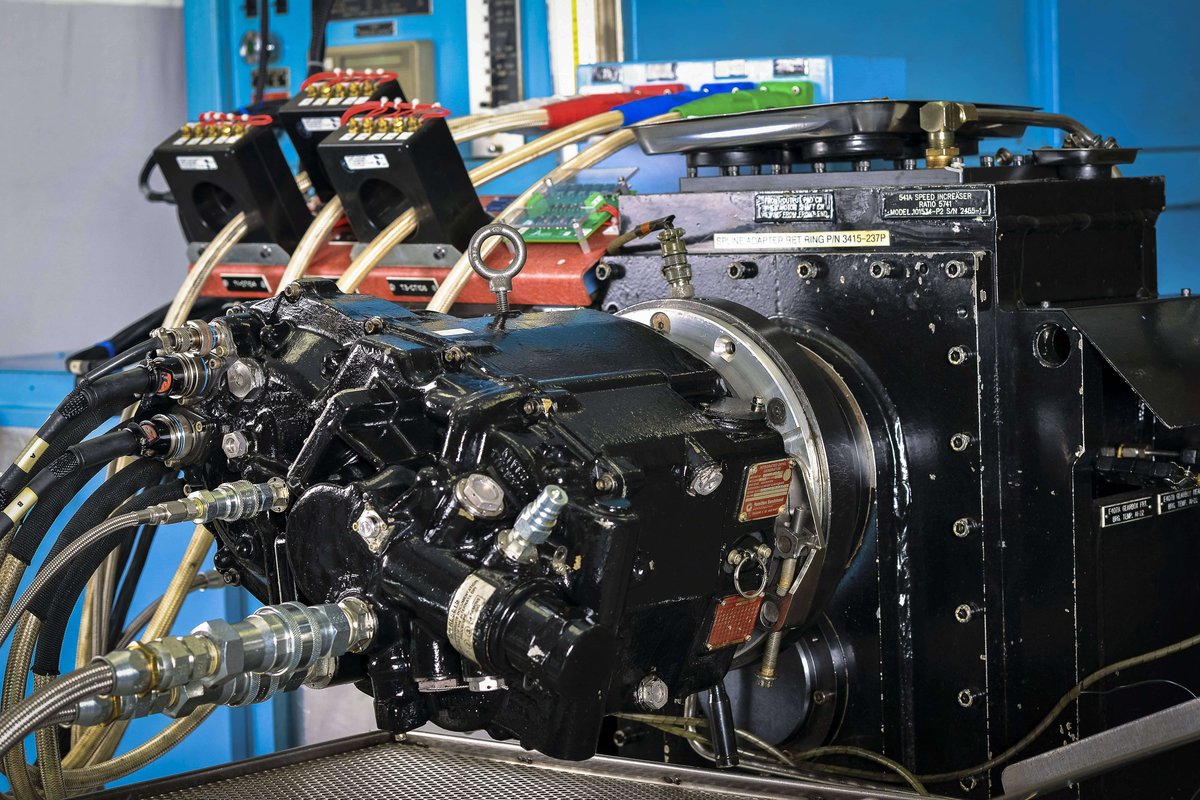

The "integrated" in Integrated Drive Generator isn't just a fancy word; it describes how two distinct, complex systems are seamlessly combined into a single, self-contained unit. These are the Constant Speed Drive (CSD) and the AC Synchronous Generator.

The Constant Speed Drive (CSD): A Hydraulic Maestro

Think of the CSD as the "brain" of the IDG, responsible for maintaining a steady beat. It's a hydro-mechanical marvel that takes the variable rotational speed from the engine's accessory gearbox and delivers a fixed, unvarying speed to the generator.

How does it achieve this magic?

- Hydraulic Power: The CSD uses hydraulic fluid under pressure, acting as a medium to transfer and regulate power. This fluid is crucial for both lubrication and controlling the internal mechanisms.

- Gears and Differential Action: Within the CSD, a sophisticated arrangement of gears, often planetary gear sets, works in conjunction with a hydraulic unit. This hydraulic unit can add or subtract speed from the mechanical input through what's known as "differential action."

- Controlled Regulation: When the engine speeds up, the CSD's hydraulic section "subtracts" speed from the input, keeping the output to the generator constant. Conversely, if the engine slows down, the CSD "adds" speed. This dynamic balancing act is governed by precise control valves that respond instantly to changes in engine RPM.

- Self-Contained Unit: The CSD, along with the generator, is sealed within a single housing, bathed in its own dedicated oil system for cooling, lubrication, and operational control.

This intricate dance ensures that, even if the engine's drive shaft is spinning at 6,000 RPM one moment and 8,000 RPM the next, the shaft driving the generator consistently maintains, for example, 12,000 RPM. This constant output speed is the foundation for producing stable electrical frequency.

The AC Synchronous Generator: The Electrical Heart

Once the CSD has done its job of delivering a constant rotational speed, it's the AC Synchronous Generator's turn. This is a standard electrical generator, but one designed for the specific demands of aircraft power.

Here's its role:

- Fixed RPM Input: It receives a precisely regulated, constant rotational speed from the CSD.

- Electrical Output: With this steady mechanical input, the generator reliably produces the required 115/200 V, 400 Hz, 3-phase AC electrical power.

- Synchronous Operation: "Synchronous" refers to the precise relationship between the generator's rotational speed and the frequency of the AC power it produces. Maintaining a constant speed ensures a constant frequency.

Together, the CSD and the generator form an unbreakable pair, each indispensable to the other's function, all within the compact, robust package of the IDG. The intricate interplay of these components is a cornerstone of modern aviation, enabling a level of electrical stability that directly impacts flight safety and operational efficiency. Delving deeper into the specifics of how an IDG manages variable engine speeds reveals a testament to precision engineering.

The IDG Operational Lifecycle: From Engine to Grid

Understanding the fundamental principles of Integrated Drive Generator operation means tracing the power flow from the engine to the aircraft's electrical distribution system. It's a continuous, closed-loop process designed for unwavering reliability.

- Engine's Mechanical Drive: The journey begins at the aircraft engine. A gearbox, typically referred to as the accessory gearbox, is directly coupled to the engine's rotating components. This gearbox provides a mechanical output shaft that spins at a speed directly proportional to the engine's RPM.

- IDG Engagement: The IDG unit is physically mounted onto this accessory gearbox. Its input shaft connects directly to the gearbox output. This means the IDG's input speed will vary with engine speed.

- CSD's Regulating Action: As the engine's variable speed drives the CSD within the IDG, the CSD's internal hydraulic and gear mechanisms spring into action. It dynamically adjusts its internal components to counteract any speed fluctuations from the engine.

- If the engine speeds up, the CSD's hydraulic unit modulates to "subtract" speed.

- If the engine slows down, the CSD modulates to "add" speed.

This precise control ensures that the output shaft of the CSD always rotates at a constant, predetermined RPM, typically around 12,000 RPM for the generator.

- Generator's Constant Output: With a constant rotational speed supplied by the CSD, the AC synchronous generator can now perform its intended function flawlessly. It converts this stable mechanical energy into stable electrical energy – specifically, the 115/200 V, 400 Hz, 3-phase AC power.

- Aircraft's Electrical Distribution: This generated power is then fed into the aircraft's main electrical bus bars. From there, it's distributed throughout the aircraft to power everything from flight deck instruments, cabin lighting, and galley equipment to the sophisticated environmental control systems and critical fly-by-wire flight control surfaces.

This entire process occurs automatically and continuously whenever the engine is operating and the IDG is engaged. The IDG doesn't just produce power; it conditions it, ensuring it meets the stringent quality requirements for safe and reliable aircraft operation.

Key Features and Design Considerations

Beyond its core function, the IDG is packed with features that underscore its critical role and the demand for high reliability in aviation.

- Automatic Speed Regulation: This is the cornerstone. The CSD continuously monitors its output speed and makes instantaneous adjustments, requiring no pilot or external intervention during normal operation.

- Self-Contained, Sealed Unit: IDGs are designed as completely self-sufficient systems. They are sealed, oil-filled units. This internal oil isn't just for lubrication; it's a vital component for cooling and, critically, for the hydraulic operation of the CSD's speed-regulating mechanism. This integrated design contributes significantly to the reliability of these self-contained power units.

- Quick Disconnect Mechanism: In the event of an IDG malfunction (e.g., overheating, severe vibration, or a mechanical failure), it can be mechanically disconnected from the engine's accessory gearbox. This can be done manually by ground crew for maintenance or, in many cases, automatically in-flight via a cockpit switch or system logic. Disconnecting a failing IDG prevents further damage to the unit or, more importantly, to the engine's gearbox.

- High Reliability & Redundancy: Given their critical function, IDGs are engineered for extreme reliability. Large aircraft typically have multiple IDGs (one per engine), providing significant redundancy. If one IDG fails, the aircraft can usually continue to operate safely on power from the remaining units, often with automatic load shedding to prioritize critical systems.

- Line-Replaceable Unit (LRU): IDGs are designed for rapid replacement. When an IDG requires servicing or fails, it's not repaired on the wing. Instead, the entire unit is swapped out for a new or overhauled one, minimizing aircraft downtime. This LRU philosophy is common for complex aircraft components.

These design principles highlight the IDG's role as a robust, intelligent, and mission-critical component that prioritizes operational integrity and maintenance efficiency.

The Lifeblood of the IDG: Oil and Its System

Perhaps one of the most underappreciated aspects of Integrated Drive Generator operation is the critical role played by its internal oil system. This isn't just about reducing friction; the oil is fundamental to the unit's cooling, lubrication, and the very hydraulic control of the Constant Speed Drive.

Multifaceted Roles of IDG Oil

- Cooling: IDGs generate a significant amount of heat during operation, both from mechanical friction and the hydraulic power transfer within the CSD. The oil circulates throughout the unit, absorbing this heat.

- Lubrication: As with any high-speed mechanical system, proper lubrication of gears, bearings, and hydraulic components is essential to prevent wear and ensure smooth operation.

- Hydraulic Control: This is where IDG oil plays a unique and critical role. The CSD relies on the precise flow and pressure of this hydraulic fluid to control its internal mechanisms, adding or subtracting speed to maintain a constant output. Without the correct oil properties and pressure, the CSD cannot regulate speed effectively.

The IDG Oil System: A Closed Loop

The IDG's oil system is a sophisticated closed loop designed to maintain optimal oil temperature, pressure, and cleanliness.

- Internal Circulation: Within the IDG, an internal pump circulates oil through the CSD and generator sections.

- External Cooling Unit: Hot oil is pumped out of the IDG, typically through a pressure fill port and filter, to an external cooling circuit.

- IDG Oil Cooler (Heat Exchanger): The most common method of cooling IDG oil is via an oil-to-fuel heat exchanger. Hot IDG oil passes through this exchanger, transferring its heat to the much cooler aircraft fuel before the fuel is consumed by the engine. This clever design not only cools the IDG but also pre-warms the fuel, improving engine performance in cold conditions.

- Return Path: Once cooled, the oil returns to the IDG, ready to absorb more heat and continue its hydraulic and lubricating functions.

This continuous circulation and cooling process are vital. Overheated oil can lose its lubricating properties, break down prematurely, and compromise the CSD's hydraulic control, leading to IDG failure. Understanding the importance of the IDG's oil system is paramount for anyone involved in aircraft maintenance.

Maintenance and Monitoring: Keeping the Power On

Given the IDG's critical function, a robust maintenance regimen is essential. Regular monitoring and timely servicing are key to preventing failures and ensuring the stable power supply the aircraft needs.

What to Monitor

- Oil Level: This is perhaps the most frequent check. IDGs are equipped with a transparent sight glass (or an electronic indicator on newer systems) to allow technicians to quickly assess the oil level. Too much or too little oil can be catastrophic.

- Oil Quality: Over time, oil can degrade due to heat, contamination, or shear forces. Technicians may periodically sample oil for analysis to check for signs of breakdown, metallic particles (indicating wear), or foreign contaminants.

- Temperature and Pressure Sensors: IDGs are fitted with sensors that continuously monitor oil temperature and pressure. These parameters are often displayed in the cockpit or on maintenance panels and are primary indicators of IDG health. Abnormal readings (e.g., high temperature, low pressure) are immediate red flags.

- Electrical Output Parameters: While the IDG's primary function is mechanical-to-electrical conversion, monitoring the electrical output (voltage, current, frequency) on the aircraft's electrical buses can indirectly indicate IDG performance.

When to Service an IDG

Servicing an IDG typically involves:

- Refilling IDG Oil: If the oil level drops below the minimum safe operating level.

- Initial Filling of Newly Installed Units: Ensuring a new IDG is properly filled before first operation.

- Adjusting Oil Levels: Bringing the level within the optimal operating range.

- Replacing Filter Elements: The oil system includes filters to trap contaminants. These need periodic replacement.

- Addressing Cooling System Issues: If the oil cooler or external cooling circuit components show signs of malfunction.

Signs of Impending Failure

Awareness of these warning signs can help prevent in-flight emergencies or costly secondary damage:

- Overheating: Indicated by high oil temperature warnings in the cockpit or on maintenance logs.

- Low Oil Pressure: A critical warning, as it can indicate insufficient lubrication or hydraulic control.

- Abnormal Vibration: Can signal internal mechanical wear or damage.

- Unusual Noises: Any grinding, whining, or hammering sounds from the IDG area.

- Fluctuating Electrical Output: While the IDG is designed for constant output, unusual variations in bus voltage or frequency (if not attributable to other systems) could point to a CSD issue.

Actionable Safety Insights: Protecting Yourself and the Aircraft

Working with IDGs involves specific safety considerations. These units operate under high pressure and temperature, and meticulous attention to detail is crucial.

Safety First When Handling IDGs

- Beware of Extreme Heat: IDG components and oil can remain scalding hot for up to an hour after engine shutdown. Always allow ample cooling time before approaching the unit. Use insulated gloves, eye protection, and appropriate protective clothing.

- Oil Level is Critical: Never operate an IDG with too much or too little oil. Overfilling can cause dangerous pressure buildups and seal failures, while underfilling leads to insufficient lubrication, overheating, and rapid damage.

- Always Use New Oil: When filling or topping off an IDG, use only new, specified aviation-grade oil. Using contaminated or incorrect oil can lead to immediate degradation of the unit's components and system failure.

- Maintain Cleanliness: Keep oil cans, funnels, and tools meticulously clean and dry. Even tiny particles of dirt or moisture can contaminate the IDG's sensitive hydraulic system.

- Consult Maintenance Manuals: Always refer to the specific aircraft's maintenance manual for detailed IDG oil cleanliness procedures, filling instructions, and safety protocols. These documents are the ultimate authority.

Common Questions About IDGs

Pilots, technicians, and even curious passengers often have questions about these vital components. Here are a few common ones:

How is a Constant Speed Drive (CSD) different from an IDG?

Historically, the CSD and the generator were often separate units, connected by a drive shaft. The CSD would perform its speed regulation, and then its output would drive a standalone generator. An IDG integrates both the CSD and the generator into a single, self-contained housing, sharing a common oil system and making it a single Line-Replaceable Unit (LRU). This integration simplifies maintenance and enhances reliability.

What happens if an IDG fails in flight?

Modern aircraft are designed with redundancy. If one IDG fails, the aircraft can typically continue to operate safely on power from the remaining IDGs (e.g., if there are two engines, two IDGs). The crew would follow specific procedures, which might include shedding non-essential electrical loads to conserve power. In some cases, an Auxiliary Power Unit (APU) generator or Ram Air Turbine (RAT) can provide emergency power. The ability for the IDG to be disconnected in flight is a crucial safety feature.

Why 400 Hz AC power? Why not 60 Hz like at home?

The 400 Hz frequency is a standard in aviation for several reasons:

- Weight Savings: Higher frequencies allow for smaller, lighter generators, transformers, and motors for a given power output, which is critical in aircraft where every pound matters.

- Efficiency: Motors and other electrical components can operate more efficiently at higher frequencies.

- Standardization: It provides a universal standard across the aviation industry, simplifying design and compatibility.

Can an IDG be repaired on the aircraft?

Generally, no. Due to their complex, sealed, and precision-engineered nature, IDGs are typically removed as a complete unit (LRU) and sent to specialized workshops for overhaul or repair. This "remove and replace" philosophy ensures that repairs are performed in controlled environments by experts, minimizing aircraft downtime.

The Unseen Hero of Stable Flight

The Principles of Integrated Drive Generator Operation represent a triumph of mechanical and electrical engineering. These self-contained, robust units are the unsung heroes of stable aircraft power, working tirelessly in the background to ensure that every system, from the most basic cabin light to the most complex fly-by-wire control, receives the precise electrical input it needs.

Their intricate blend of hydraulics and mechanics within the Constant Speed Drive, coupled with the reliable output of the synchronous generator, makes them indispensable. Understanding their design, operational characteristics, and the critical role of components like the internal oil system isn't just for mechanics and engineers; it's a testament to the layers of innovation that contribute to the safety and capability of modern air travel. The next time you step onto a large airliner, remember the silent, powerful work being done by its Integrated Drive Generators, ensuring a smooth and electrically stable journey. To truly appreciate the breadth of power generation in aviation, a deeper dive into the world of aircraft IDGs is invaluable.