In the intricate world of aviation, the reliability of electrical power is not just a convenience—it's a non-negotiable cornerstone of safety and operational efficiency. Every modern aircraft, from commercial airliners to sophisticated military jets, relies on a constant, unwavering supply of electricity to power everything from critical avionics and flight controls to cabin lighting and environmental systems. At the heart of this vital network stands an unsung hero: the Integrated Drive Generator (IDG).

This flagship guide serves as your comprehensive hub, illuminating the complexities and critical importance of the IDG. We'll explore how this ingenious piece of engineering ensures that your aircraft always has the stable power it needs, bridging the gap between fluctuating engine speeds and the rigid demands of onboard electrical systems. To truly grasp the essence of this remarkable device and its foundational role, it's beneficial to start by understanding the Principles of Integrated Drive Generator.

The Unsung Hero of Aircraft Power: Why Every Flight Relies on the Integrated Drive Generator

Imagine trying to power a sophisticated computer system directly from an engine that's constantly changing speed – it wouldn't work. Modern aircraft require a precise, stable 115/200 V, 400 Hz, 3-phase AC power supply. The IDG is precisely engineered to fulfill this demand, acting as a sophisticated bridge that translates the engine's variable rotational speed into the perfectly regulated electrical output essential for aircraft operations.

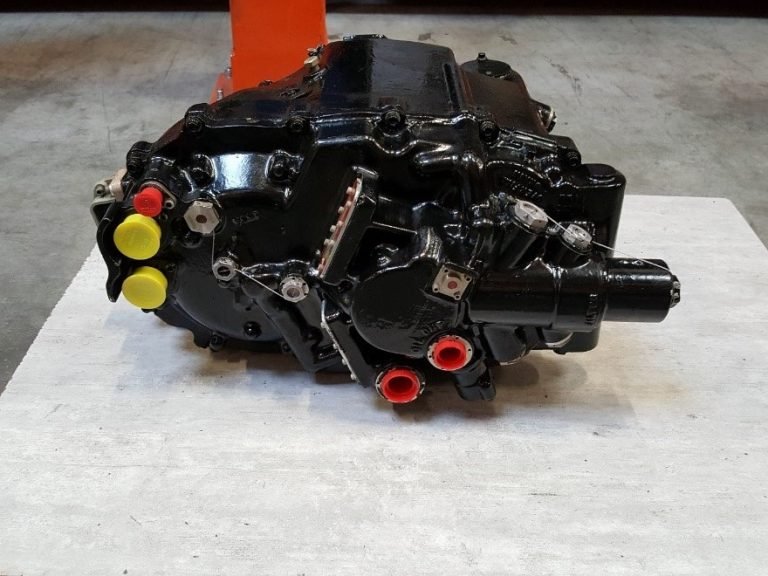

More than just a simple generator, the IDG is a self-contained marvel. It cleverly integrates two distinct, yet interdependent, units: a Constant Speed Drive (CSD) and an AC generator, all housed within a single, robust casing. This unified design is key to its high reliability and performance, ensuring that vital systems receive power without interruption, regardless of whether the engine is idling or at full thrust.

At the Heart of the System: How the IDG Delivers Unwavering Electrical Stability

The magic of the IDG lies in its ability to maintain a constant output frequency despite varying engine speeds. It achieves this through a hydro-mechanical transmission system within the CSD. As the aircraft engine's accessory gearbox drives the IDG, the CSD steps in, using hydraulic fluid, gears, and finely tuned control valves to convert that variable input speed into a consistent, unvarying rotational speed for the internal AC generator. This precision engineering ensures that the synchronous AC generator can then consistently produce the required 400 Hz AC power.

A vital component in this delicate dance of speed and power is the IDG's sophisticated oil system. Oil isn't just for lubrication; it's the lifeblood of the CSD, crucial for cooling, lubrication, and, most importantly, mechanically controlling the rotational speed. Its quality, cleanliness, and quantity are paramount for the IDG's reliability and longevity. To truly appreciate the intricate engineering that makes this possible, we invite you to explore the Key Components and Architecture of the IDG in more detail.

The IDG's oil system is a closed loop, encompassing the IDG unit itself, an external cooling unit, and an IDG oil cooler—often an efficient oil-to-fuel heat exchanger. Oil is continuously pumped from the IDG, through a pressure fill port and filter, to this external circuit where it's cooled before returning to the unit. Monitoring this critical fluid is straightforward, often done via a transparent sight glass, allowing technicians to quickly check the oil level.

Powering the Skies: IDG's Essential Role in Aircraft Systems

The stable electrical power generated by the IDG feeds directly into the aircraft's primary electrical distribution system, becoming the backbone for an array of critical functions. Without this consistent power, modern flight would be impossible. Consider the systems that depend entirely on the IDG:

- Avionics: From navigation and communication systems to flight management computers, all rely on a clean, stable power supply.

- Environmental Control: Heating, ventilation, and air conditioning systems that ensure passenger comfort and equipment temperature regulation.

- Lighting: Cockpit, cabin, and exterior lighting systems.

- Fly-by-Wire Systems: The sophisticated electronic controls that translate pilot input into flight surface movements.

The seamless integration of the IDG into the broader aircraft electrical network is a testament to careful system design. Understanding how this power is distributed and managed across the entire aircraft is crucial for any aviation professional, prompting a Deep dive into IDG integration to fully appreciate its impact.

Safeguarding Performance: The Criticality of IDG Maintenance and Upkeep

Given its pivotal role, the IDG is designed for robust performance and ease of maintenance. Typically, IDGs are Line-Replaceable Units (LRUs), meaning they are swapped as complete units rather than being repaired on-wing, simplifying turnaround times during maintenance. However, regular servicing is still absolutely vital to ensure continued reliability and peak performance.

Crucial Considerations for IDG Oil Management

Maintenance tasks frequently involve interaction with the IDG's oil system, which is paramount for its operational health:

- Refilling and Adjusting Oil Levels: Ensuring the correct oil quantity is critical; too much or too little can cause severe damage.

- Initial Fills: New or newly-installed IDGs require precise oil filling procedures.

- Filter Element Replacement: Keeping the oil clean from contaminants is key to preventing premature wear and system degradation.

- Cooling System Maintenance: Ensuring the external cooling unit and heat exchangers are functioning optimally is essential for thermal management.

The aircraft's specific maintenance manual provides detailed guidance on oil cleanliness procedures and other servicing protocols, emphasizing the use of new, clean oil to prevent contamination and rapid degradation.

Prioritizing Safety During IDG Servicing

Working with IDGs demands strict adherence to safety protocols. Engine components, including the IDG itself, can retain extreme heat for up to an hour after engine shutdown, with the internal oil remaining scalding hot. Therefore, always wear appropriate Personal Protective Equipment (PPE), including goggles, insulated gloves, and protective clothing, to prevent severe burns. Additionally, always use new, clean oil during filling or topping off procedures, and ensure all tools and oil cans are kept in a clean, dry environment to prevent any foreign object debris (FOD) or contamination. To delve deeper into the specifics of caring for these vital units, consult the comprehensive guide on Maintenance, Overhaul, and Repair Procedures.

Navigating Challenges: Identifying and Addressing IDG System Faults

Despite their robust design, IDGs can encounter issues. Recognizing the early signs of trouble is key to preventing more serious damage or in-flight complications. Common indicators of impending failure often include:

- Overheating: Indicated by high temperature readings from internal sensors.

- Low Oil Pressure: Signaling issues within the lubrication or hydraulic control system.

- Abnormal Vibration: Suggesting internal mechanical wear or imbalance.

The IDG is equipped with safety features, such as a quick disconnect mechanism, which allows the unit to be mechanically disengaged from the engine in case of a severe internal failure, preventing damage to the engine accessory gearbox. Understanding these symptoms and the appropriate responses is crucial for maintenance personnel. For a more detailed understanding of how to diagnose and address potential problems, our guide on Troubleshooting Common IDG System Faults offers invaluable insights.

The Future of Stable Power in Aviation

The Integrated Drive Generator remains a cornerstone of aircraft electrical systems, continually evolving with advancements in materials science, control electronics, and hydraulic technologies. As aircraft demand even more electrical power for increasingly sophisticated systems—from electric taxiing to advanced sensor arrays—the role of the IDG, or its next-generation successors, will only become more critical. Ensuring stable, reliable power under all flight conditions is not just a present necessity, but a foundational requirement for the future of flight.